What to pay attention to when installing rotary joint

2021-05-13

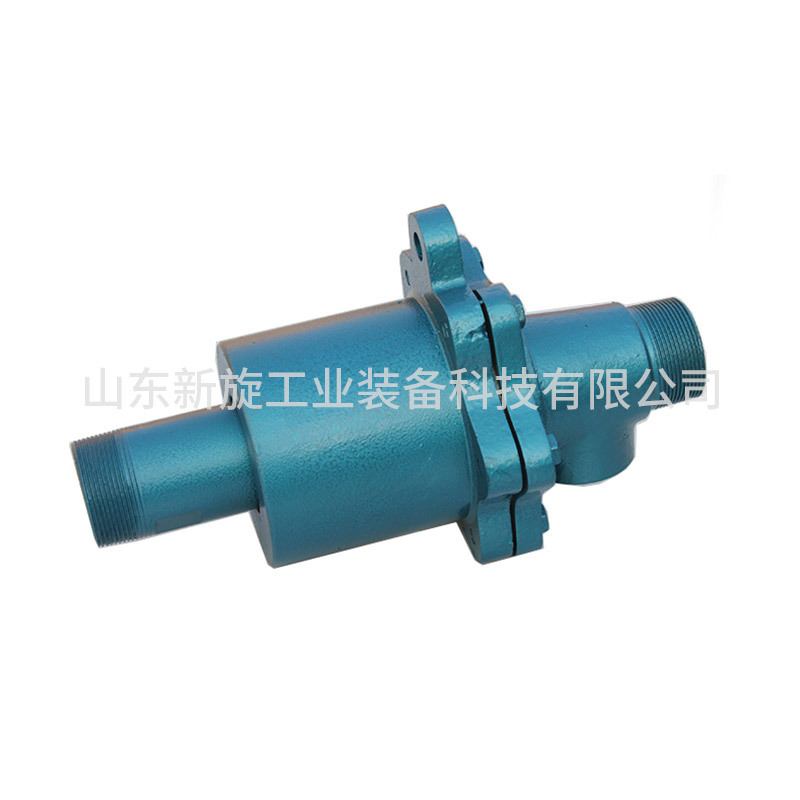

Notes on installation of rotary joints.

1. Before installation, make sure that no foreign matter is mixed into the sealing surface. For connectors with inspection holes, install them with the inspection holes facing down.

2. When installing the pipeline, avoid installing heavy objects such as valves on the rotary joints.

3. In the case of threaded installation, the thread direction should be easy to tighten relative to the direction of rotation. The direction of rotation of the rollers, drums, etc., viewed from the installation direction of the rotary joint, should be: the clockwise direction is the left thread, and the counterclockwise direction is the right thread.

4. For the connection between the rotary joint and the piping part, please use a flexible pipe. Please avoid using steel pipes to install the pipeline directly, so that the joints are restricted.

5. When the rotating joint is stopped, please only stop the joint, and no other restrictions are allowed. Under the highest operating pressure, please avoid using the highest speed.

6. When used under high temperature conditions, if the bearing uses ball bearings, grease must be supplied. If it exceeds a certain time, it must be oiled.

7. When lubricating grease, please remove the plug to apply grease.

8. Please do not leave it for a long time when it is stopped. Otherwise, it may rust and cause fluid leakage.

9. For joints with inspection holes, if fluid leaks from the inspection holes, it is time to replace them.

10. In case of failure, please repair it or replace it with a new one in time. In the state of fluid leakage, please do not continue to operate, otherwise it may cause a major accident.

Keywords:

Pipeline Connectors

Previous:

Related News

More Products

The leading products include rotary joints, metal hoses, warehouse pumps, cable hoses (plastic-coated pipes), compensators, quick connectors, siphons, flowmeters, sealing rings and other supporting products