Product category

CONTACT US

Address: No. 567, Xingye Road, Economic Development Zone, Tengzhou City

TEL:+86-0632-5505899

FAX:+86-0632-5566466

E-Mail:sales@xin-xuan.com

- Description

-

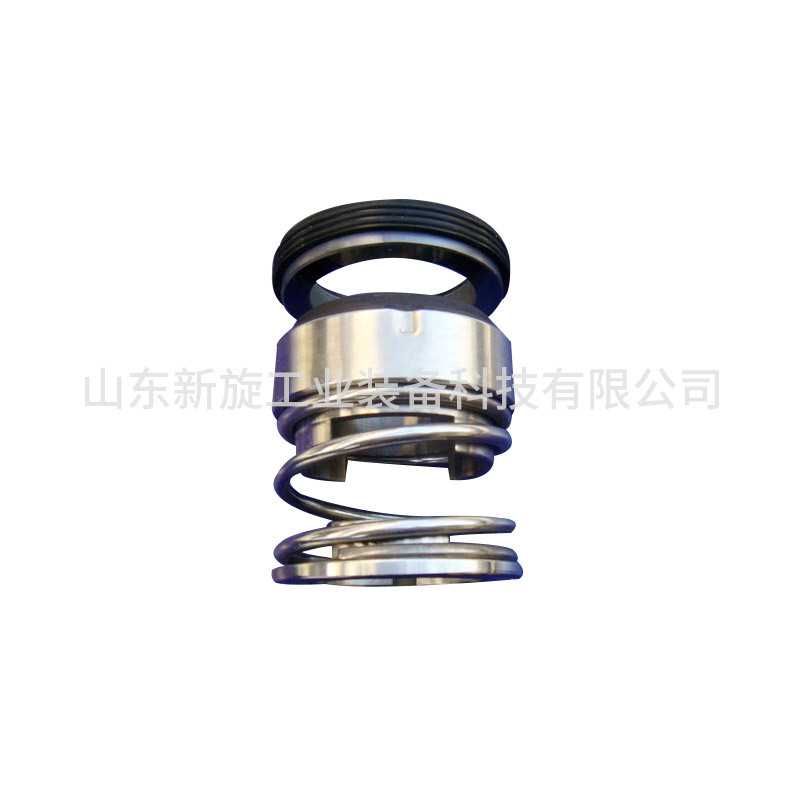

Detailed description of mechanical seal

A mechanical seal refers to a device for preventing fluid leakage that is composed of at least a pair of end surfaces perpendicular to the axis of rotation under the action of fluid pressure and the elastic force (or magnetic force) of the compensation mechanism and the cooperation of the auxiliary seal to keep fit and slide relatively.

The elastic loading mechanism and the auxiliary seal are the mechanical seals of the metal bellows, which we call the metal bellows seal. In light-duty seals, there is also the use of a rubber bellows for the left auxiliary seal. The rubber bellows has limited elasticity and generally needs to be supplemented with a spring to meet the loading elasticity. "Mechanical seal" is often referred to as "mechanical seal".

Mechanical seal is a shaft sealing device for rotating machinery. Such as centrifugal pumps, centrifuges, reactors and compressors and other equipment. Since the rotating shaft runs through the inside and outside of the equipment, there is a circumferential gap between the shaft and the equipment, and the medium in the equipment leaks outward through the gap. If the pressure in the equipment is lower than the atmospheric pressure, the air leaks into the equipment, so there must be a Shaft seal to prevent leakage. There are many types of shaft seals. Because mechanical seals have the advantages of less leakage and long life, all mechanical seals in the world are the most important shaft seal method for these equipment. Mechanical seals are also called end face seals. They are defined in relevant national standards as follows: "At least a pair of end faces perpendicular to the axis of rotation are kept close together under the cooperation of fluid pressure and the elastic force (or magnetic force) of the compensation mechanism and the auxiliary seal. A device that prevents fluid leakage by sliding relative to each other.

The main components

East ring, static ring, cooling device and compression spring (depending on the specific equipment).

Auxiliary seal

Sealing ring (including O type, X type, U type, rectangular flexible graphite, PTFE coated rubber O ring, etc.).

Elastic force compensation mechanism

Spring, push ring. Spring seat and key or various screws.

Classification Divided into single end face, double end face; balanced type, unbalanced type; arbitrary rotation direction, fixed rotation direction, etc.

Principle overview

The mechanical seal is a shaft sealing device that relies on a pair or several pairs of end faces that are perpendicular to the shaft for relative sliding under the action of fluid pressure and the elastic force (or magnetic force) of the compensation mechanism, and is equipped with an auxiliary seal to achieve leakage prevention.

Common mechanical seal structure is composed of stationary ring (static ring), rotating ring (moving ring), elastic element spring seat, set screw, rotating ring auxiliary sealing ring and stationary ring auxiliary sealing ring and other elements to prevent the pin from being fixed on the gland To prevent the stationary ring from rotating.

Rotating rings and stationary rings can often be called compensation rings or non-compensation rings depending on whether they have axial compensation capabilities.

skills requirement

The seal ring is the general name of the moving ring and the static ring, and it is the most important component of the mechanical seal. The seal ring determines the performance and life of the mechanical seal to a large extent, therefore, some requirements are put forward for it.

Have enough strength and rigidity

Under working conditions (such as pressure, temperature and sliding speed, etc.), the deformation should be as small as possible, and the tightness can still be maintained when the working conditions fluctuate. In particular, the sealing end face must have sufficient strength and a certain degree of corrosion resistance to ensure that the product has a satisfactory service life.

Have good thermal shock resistance

For this reason, the material is required to have a higher thermal conductivity and a smaller linear expansion coefficient, so that it will not crack when subjected to thermal shock.

Small coefficient of friction

The sealing ring matching should have a small friction coefficient.

Good self-lubricating

If a short period of dry friction occurs during work, the sealing end face will not be damaged. Therefore, the seal ring must have good self-lubricating properties, and the seal ring material and the sealing fluid must have good wettability.

Simple structure

The structure of the seal ring should be simple and symmetrical. The overall structure is preferred. Combined (such as inlaid) seal ring can also be used. Avoid using the sprayed structure of the seal end surface as much as possible.

The sealing ring should be easy to process and manufacture

Installation and maintenance should be convenient, and the price should be low.

Preparation before startup

1. Comprehensively check the mechanical seal, whether the attachments and pipeline installation are complete, and whether they meet the technical requirements.

2. Before starting the mechanical seal, perform a static pressure test to check whether the mechanical seal is leaking. If there are too many leaks, find out the cause and try to eliminate it. If it is still invalid, it should be disassembled, checked and reinstalled. Generally, the static pressure test pressure is 2~3 kg/cm².

3. Rotate the pump to the crank to check whether it is brisk and even. If the crank is difficult or does not move, check whether the assembly size is wrong and whether the installation is reasonable.

Installation and shutdown

1. Keep the sealed cavity filled with liquid before starting. When transporting solidified media, steam is used to heat the sealed cavity to melt the media. The car must be cranked before starting to prevent the soft ring from breaking due to sudden start.

2. For mechanical seals that use the external oil sealing system of the pump, the oil sealing system should be activated first. The oil sealing system is finally stopped after stopping.

3. After the hot oil pump is shut down, the cooling water in the oil seal cavity and the end seal should not be stopped immediately. The cooling water should be stopped when the oil temperature at the end seal drops below 80 degrees to avoid damaging the sealing parts.

Running

1. If there is a slight leakage after the pump is started, it should be observed for a period of time. If the leakage does not decrease after 4 hours of continuous operation, the pump should be stopped for inspection.

2. The operating pressure of the pump should be stable, and the pressure fluctuation should not exceed 1 kg/cm².

3. During the operation of the pump, the pumping should be avoided to avoid dry friction on the sealing surface and damage to the seal.

3. The sealing condition should be checked frequently. During operation, when the leakage exceeds the standard, the heavy oil should not exceed 5 drops/min, and the light oil should not exceed 10 drops/min. If there is no improvement trend within 2-3 days, the pump should be stopped to check the sealing device.

advantage

1. Reliable sealing. In the long-term operation, the sealing state is very stable, and the leakage is very small. According to rough statistics, the leakage is generally only 1/100 of the soft packing seal;

2. Long service life in oil and water media generally can reach 1 to 2 years or longer, and in chemical media, it can usually reach more than half a year;

3. The frictional power consumption is small. The frictional power of the mechanical seal is only 10% to 50% of that of the soft packing seal;

4. The shaft or sleeve is basically free from wear;

5. The end face can be automatically compensated after the long maintenance period is worn out, under normal circumstances, no frequent maintenance is required;

6. Good vibration resistance, insensitive to the vibration and deflection of the rotating shaft and the deflection of the shaft to the sealed cavity;

7. A wide range of applications. Mechanical seals can be used for sealing at low temperature, high temperature, vacuum, high pressure, different speeds, as well as various corrosive media and media containing abrasive particles.

8. For the "zero leakage" needs of many factories, the packing seal cannot meet this requirement; it is basically suitable for a wide range and greater arbitrariness, but for the factory, frequent replacement or maintenance will cause great losses to the factory.

Shandong Xinxuan Industrial Equipment Technology Co., Ltd.

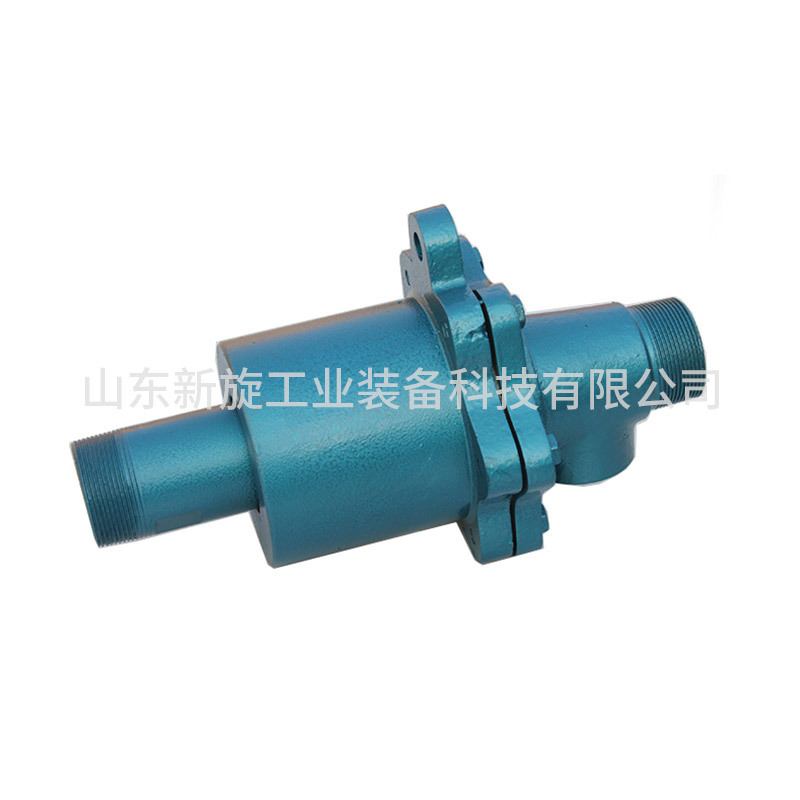

Xinxuan Company is a company engaged in the development of pipelines and pipeline connectors. The leading products include rotary joints, metal hoses, warehouse pumps, cable hoses (plastic-coated pipes), compensators, quick connectors, siphons, flowmeters, sealing rings and other supporting products. Widely used in steel, paper, rubber, plastic, petroleum, chemical, building materials, textile printing and dyeing, chemical fiber, drying, packaging, glass, tobacco, food, medicine and other industries.

Keywords:

Previous:

Next:

Shandong Xinxuan Rotary Joint R&D Center

Honest enterprise

Membership card

Business license

Our advantage

Our years of accumulated experience, our technology and continuous innovation, and our honest service have won unanimous affirmation and praise from customers in the industry, and have won goodwill for the company

Many years of experience

20 years of industry experience, quality is guaranteed, leading products include rotary joints, metal hoses, warehouse pumps, cable hoses (plastic-coated pipes), compensators, quick connectors, siphons, flowmeters, sealing rings and other supporting products

Customized products

Products of different specifications can be customized according to customer requirements to meet customer needs

Dedicated design team

The company currently has 24 design engineers with many years of industry experience; it has sent teams to the Johnson Company of the United States for investigation and study, and introduced technologies such as American spherical grinders and tungsten carbide mechanical seals.

High-quality products

From raw material selection, processing technology, surface treatment to process assembly, the quality system standards are strictly implemented to deliver your qualified products

Wide range of application industries

Widely used in steel, paper, rubber, plastic, petroleum, chemical, building materials, textile printing and dyeing, chemical fiber, drying, packaging, glass, tobacco, food, medicine and other industries

A good after-sales service

For product quality problems, there is no reason to compensate for the loss within 15 days, and the trust of customers should be respected

Inquiry Now

If you are interested in our products, please leave your e-mail, we will contact you as soon as possible, thank you!

More Products

The leading products include rotary joints, metal hoses, warehouse pumps, cable hoses (plastic-coated pipes), compensators, quick connectors, siphons, flowmeters, sealing rings and other supporting products