What are the sealing methods of rotary joints and the specifications of the seals

2021-05-13

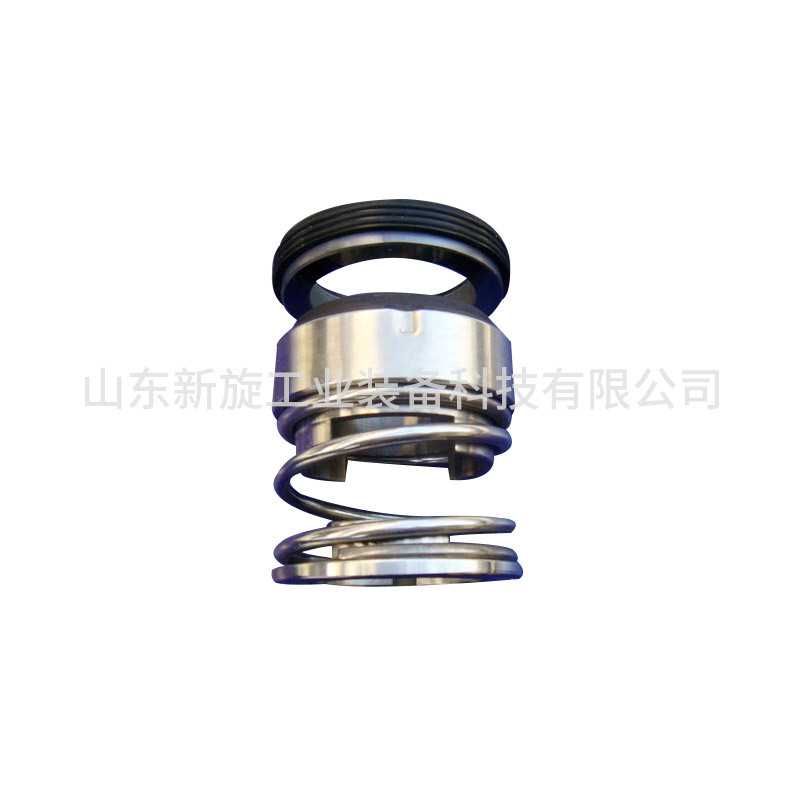

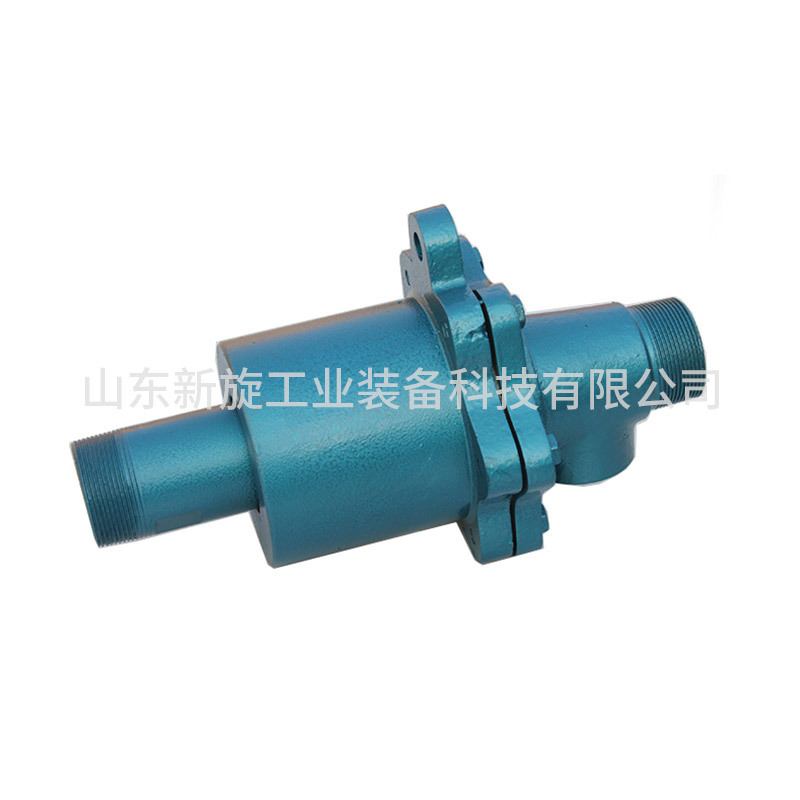

The rotary joint is a sealed transmission device. According to the requirements of the use environment and transmission medium, different sealing rings will be selected to play a sealing role in the grease-lubricated gap to prevent debris or dust from entering the joint and reduce friction at the same time. Reduce heat and wear; but the seal ring is a vulnerable part of the rotary joint. It not only has to withstand the pressure of the internal medium, but also withstand the friction between the outside and the shell. The following is an introduction to the commonly used seal ring of the rotary joint.

There is a fluid dynamic pressure film controlled by the cutting edge between the oil seal inside the rotary joint and the shaft, so that the liquid film is in contact with the air and forms a meniscus under the action of the surface tension of the liquid to realize the sealing of the rotary joint rotary shaft to prevent The role of leakage; the meniscus is a necessary condition for oil seal sealing, and the thickness of the oil film directly affects the sealing ability of the oil seal; too much oil film thickness of the rotary joint will cause leakage, and too small oil film thickness may cause dry friction, leading to oil seal wear and critical ink Is the most ideal. .

Rotary joint silicon carbide graphite ring is a ring-shaped sealing material made of silicon carbide; the alumina sealing ring used in high-temperature rotary joints, also called ceramic sealing ring, is a medium-sized sealing ring made of alumina material, which is resistant to Features of high temperature and high strength; a relatively heavy cemented carbide sealing ring made of cemented carbide materials. Of course, the seal rings of different materials play different roles on the rotary joint. Only when used correctly can the maximum effect be achieved. If you find a slight leak in the rotary joint, you should check the sealing ring and other wearing parts in time, and replace them in time. . The sealing performance of the composite material seal is relatively better, and it is used where the hydraulic cylinder has an intermediate positioning. The rotary joint sealed with composite materials can make the rotary joint more compact and exquisite due to the small size of the seal itself. The cost of the composite seal itself is much cheaper than that of the mechanical seal. The composite rotary seal is composed of two parts, which is composed of an outer ring and an O-ring. The O-ring plays the role of supporting the outer ring, making the entire rotary seal easier to install.

Keywords:

Pipeline Connectors

Related News

More Products

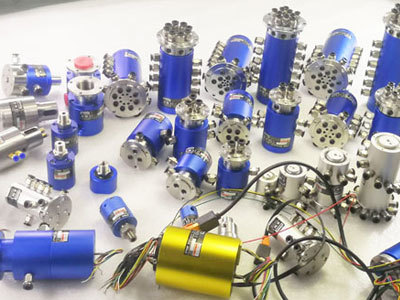

The leading products include rotary joints, metal hoses, warehouse pumps, cable hoses (plastic-coated pipes), compensators, quick connectors, siphons, flowmeters, sealing rings and other supporting products