How to maintain the wear of the rotary joint

2021-05-13

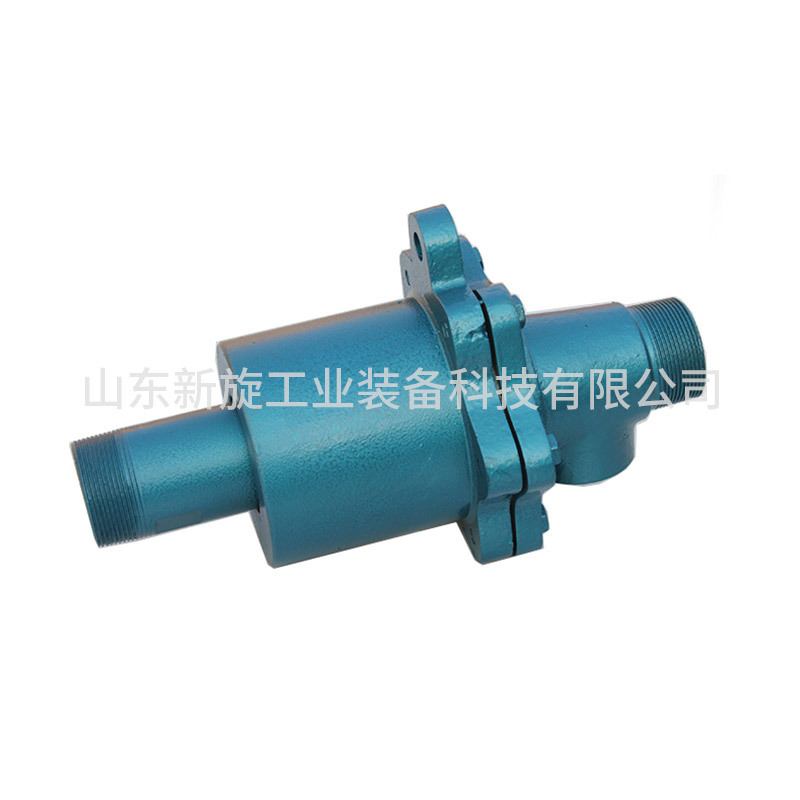

Today, I will tell you how to maintain the rotary joint after it has been used for a period of time. Let's take a look at the daily maintenance knowledge of rotary joints.

1. Keep the rotary joint drum and the inside of the pipe clean. Special attention should be paid to new equipment, and filters should be added when necessary to avoid abnormal wear of the rotary joint caused by foreign objects.

2. As the machine is not used for a long time, it will cause scaling and rust in the rotary joint. Please be aware that it may jam or drip when it is used again.

3. If there is an oil injection device, please oil it regularly to ensure the reliability of the rotation of the rotary joint bearing.

4. The rotary joint that circulates the heating medium should gradually generate temperature to avoid sudden temperature changes.

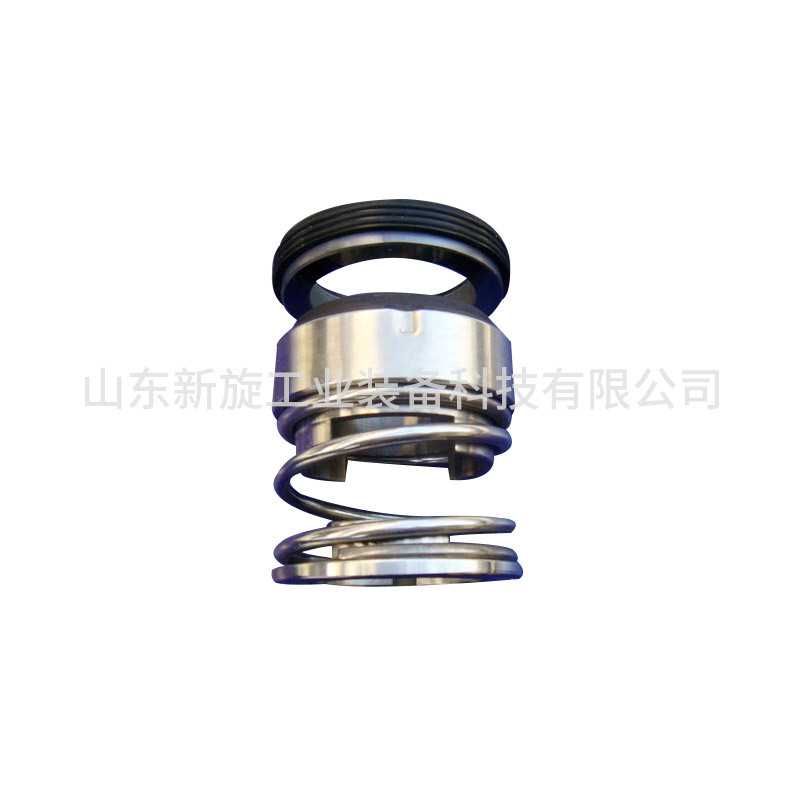

5. Check the wear condition and thickness change of the sealing surface; observe the friction track of the sealing surface to see if there are three-point discontinuity or scratches. If there is the above condition, it should be replaced immediately.

Keywords:

Pipeline Connectors

Related News

More Products

The leading products include rotary joints, metal hoses, warehouse pumps, cable hoses (plastic-coated pipes), compensators, quick connectors, siphons, flowmeters, sealing rings and other supporting products